Axl Imperial is an international manufacturer and supplier of automation, measurement control and testing devices for advanced industrial and laboratory use.

Utilising the design of state-of-the-art equipment and know-how in the field of automation and high-precision industrial measurement and control, Axl Imperial offers production processes and automation solutions to the most demanding needs of modern industry.

Consisting of a variety of engineers, each with great experience in specific industrial segments as automation, motion, measurement and control, the company provides integrated services, from design, development and installation of industrial equipment, to technical consulting, service and after-sales support, for all industrial needs as high precision in-line and laboratory measurements and quality control.

Axl Imperial seeks to constantly improve the quality of the services and systems provided, with the sole criterion, the principle, that quality and economy in production are the key prerequisites for a healthy industrial development and high quality products.

Axl Imperial’s industrial automation applications

for higher efficiency, improved quality, and enhanced consistency.

Efficiency, Advancement,

Cost Savings

Explore Cases

of Advancing

Industries with

Axl Imperial's

Automation Solutions.

Case Studies

Pill Inspection

in Blister Packaging

The client, Lavipharm Pharmaceutical Company, faced the challenge of ensuring the presence and integrity of all pills in blister packaging. They needed a reliable solution to detect any shortages and maintain high-quality standards.

To address Lavipharm's requirements, Axl Imperial implemented a Vision System specifically designed for pill inspection in blister packaging. The system utilized the advanced KEYENCE CV-X Intuitive Vision System, equipped with a high-resolution 2M pixels camera and a rapid inspection speed of 100ms per inspection. This allowed for up to 10 inspections per second, ensuring efficient and accurate detection.

In addition, Axl Imperial integrated the user-friendly KEYENCE CA-MP120T 12-inch multitouch panel, providing precise control and intuitive interaction for seamless operation. The inclusion of the LED BAR 24VDC 10W Lighting further optimized the inspection process, enhancing accuracy and efficiency.

The implemented solution offered numerous benefits to Lavipharm Pharmaceutical Company. It successfully detected the presence or absence of pills in blister packaging, addressing the primary concern of pill integrity. The system's measurement accuracy of up to ¼ shortage per pill in the entire package ensured high-quality control.

With Axl Imperial's Vision System, Lavipharm achieved improved quality assurance, increased efficiency, and streamlined blister packaging processes. The solution provided reliable and precise results, minimizing errors and optimizing the overall pill inspection workflow.

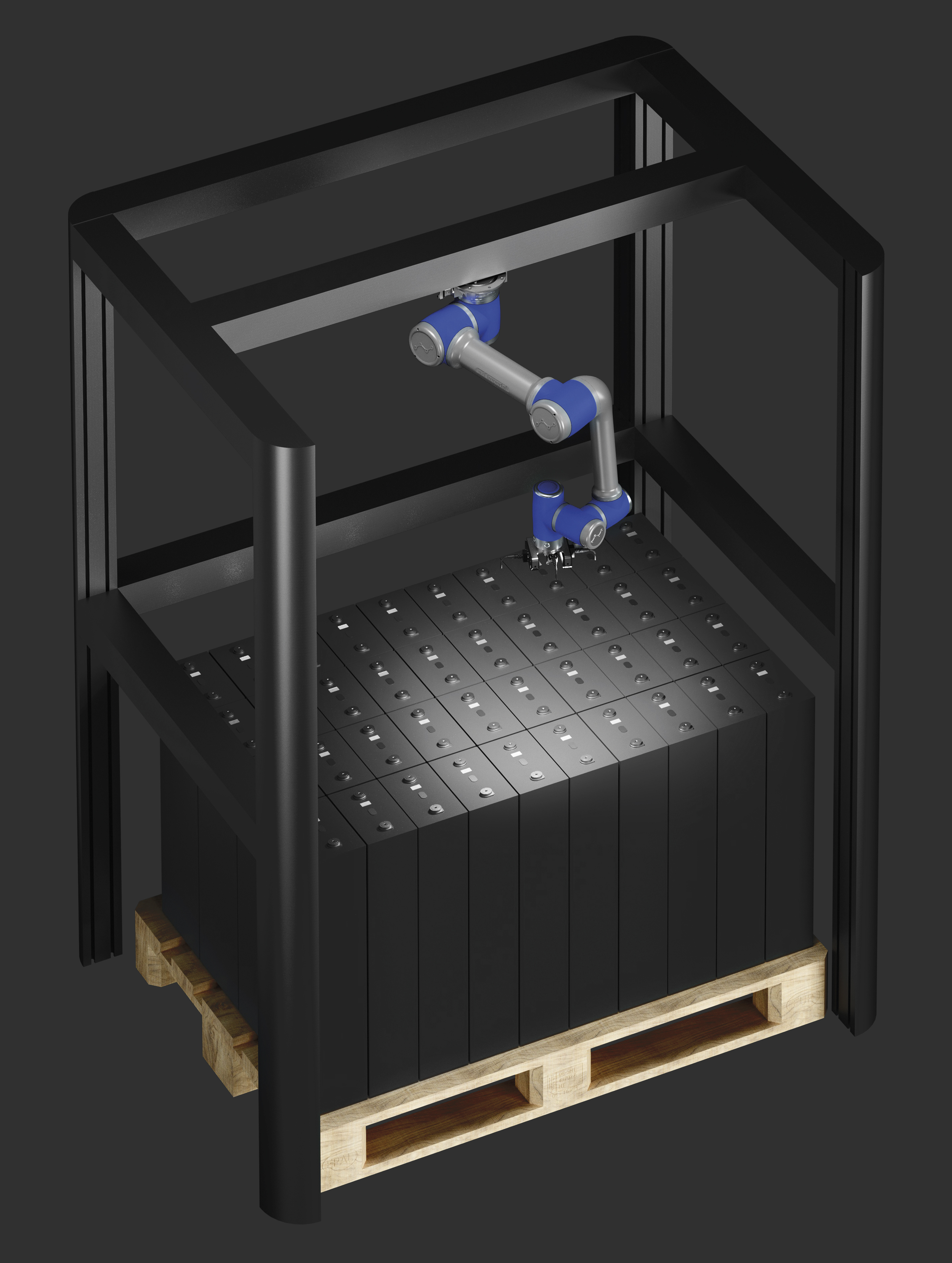

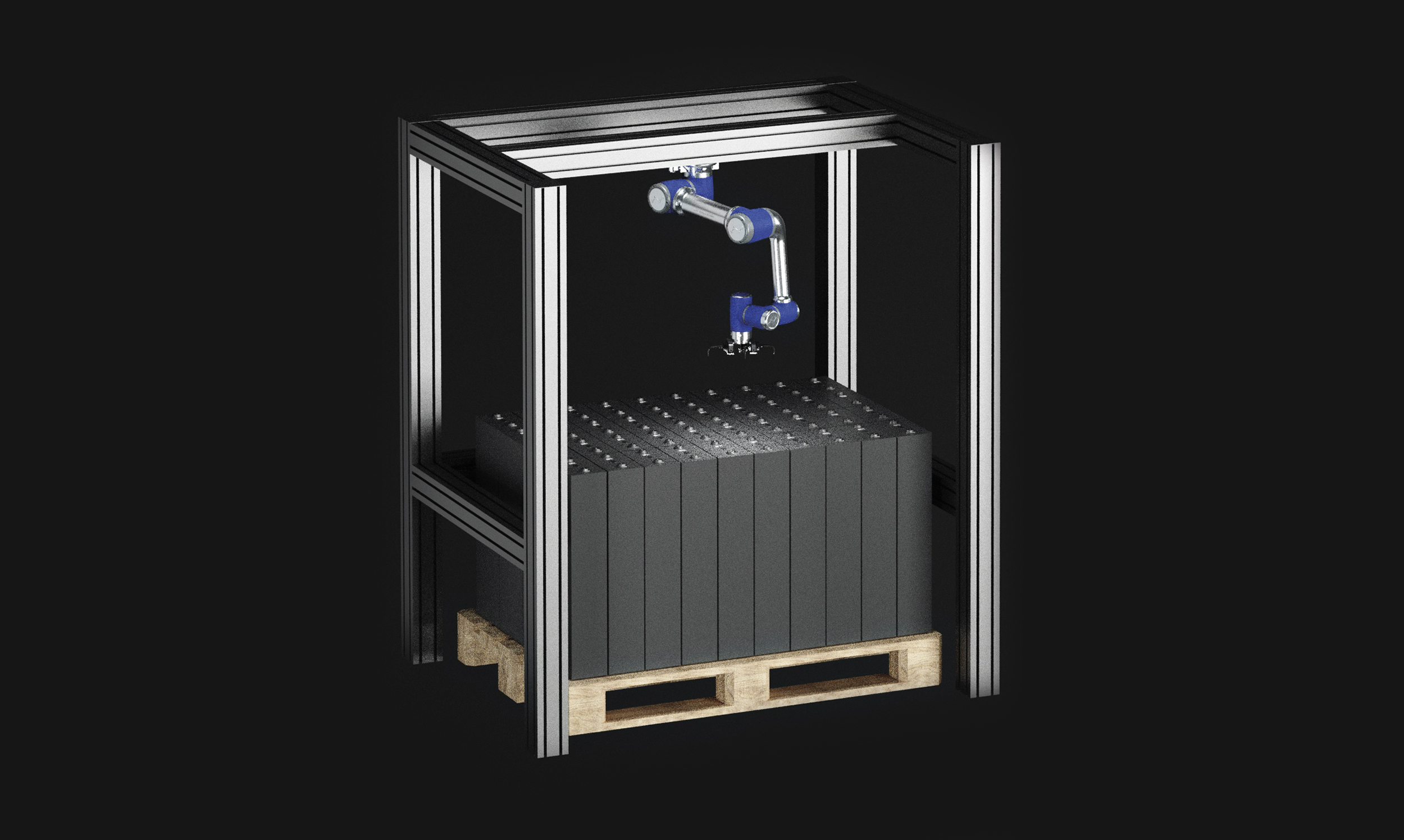

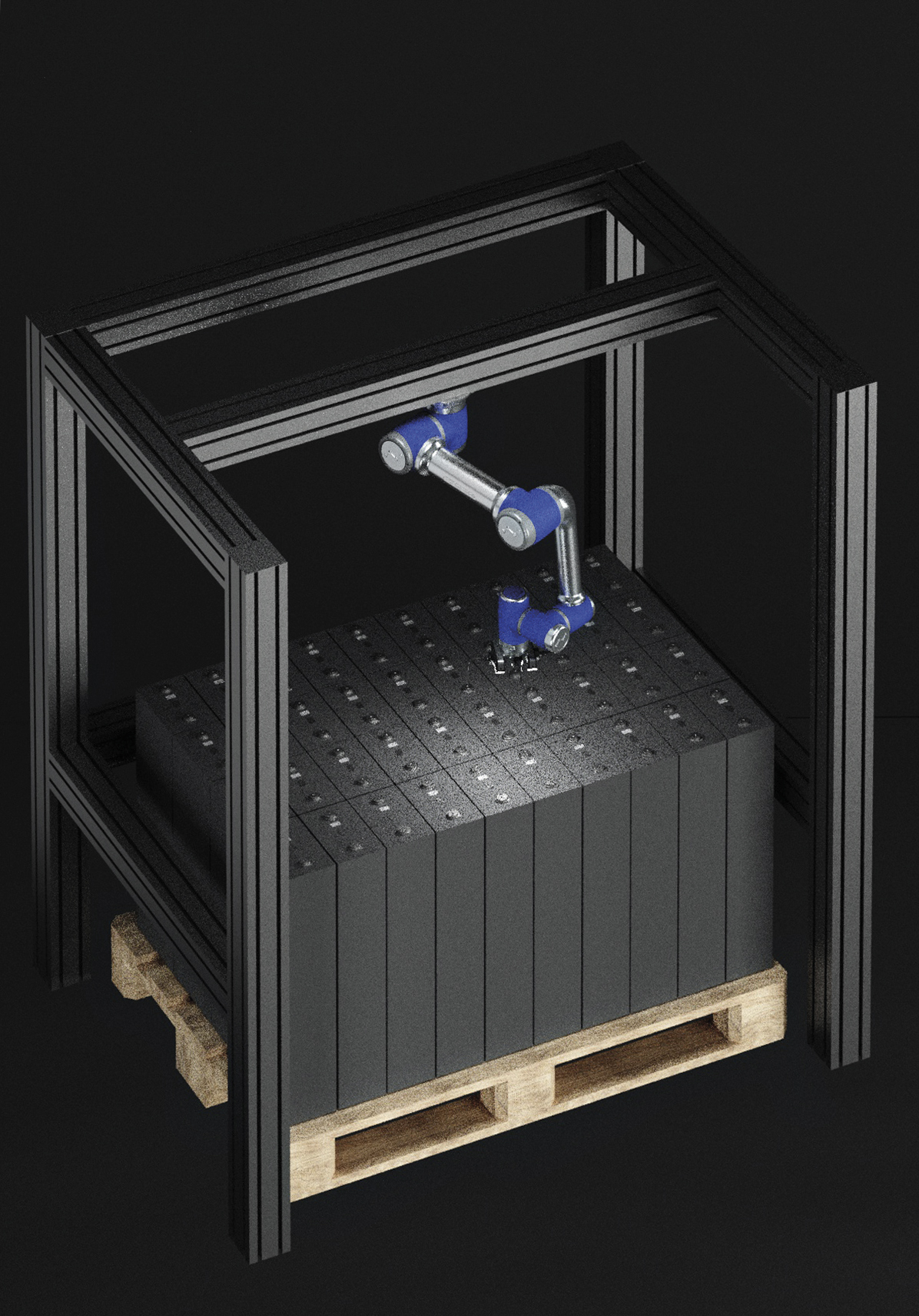

Polar Alignment

and Height of Poles in Lead-Acid Batteries

The client faced challenges in controlling the polar alignment and height of poles during the palletization stage of lead-acid battery production. Manual processes led to inconsistencies and errors, affecting overall battery quality and efficiency.

A comprehensive robotic control system was implemented to address the alignment and height control of lead-acid batteries. The system consisted of a 6-axis robotic arm, KEYENCE industrial vision system, and KEYENCE height difference measurement system. The height difference measurement system utilized KEYENCE IL series distance measurement laser heads to ensure precise measurements and facilitate PASS/FAIL indication based on predefined values.

The implemented robotic control system ensured accurate polar alignment and height control of poles in lead-acid batteries, improving overall battery quality and consistency. By automating these processes, the system increased production efficiency, reduced errors, and enhanced overall operational performance. Additionally, the system's modular design allowed for easy integration and scalability, providing flexibility for future production needs. The client experienced improved productivity, cost savings, and enhanced product quality.

Dimensional Inspection

and Packaging of Plastic Components

The client faced the challenge of improving their quality control procedures while increasing productivity and reducing costs. They sought a solution that would automate the process, eliminate human errors, and enhance overall efficiency.

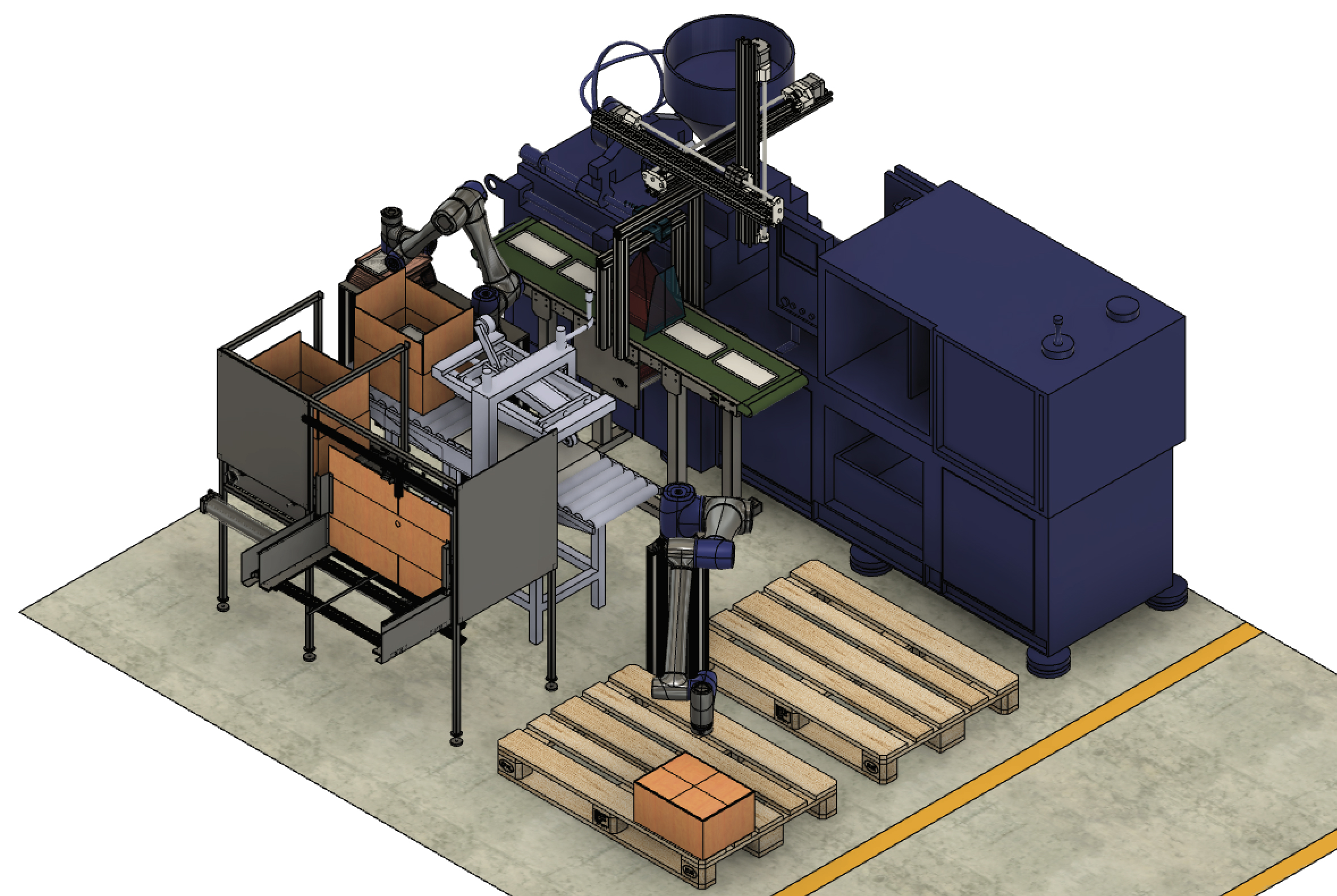

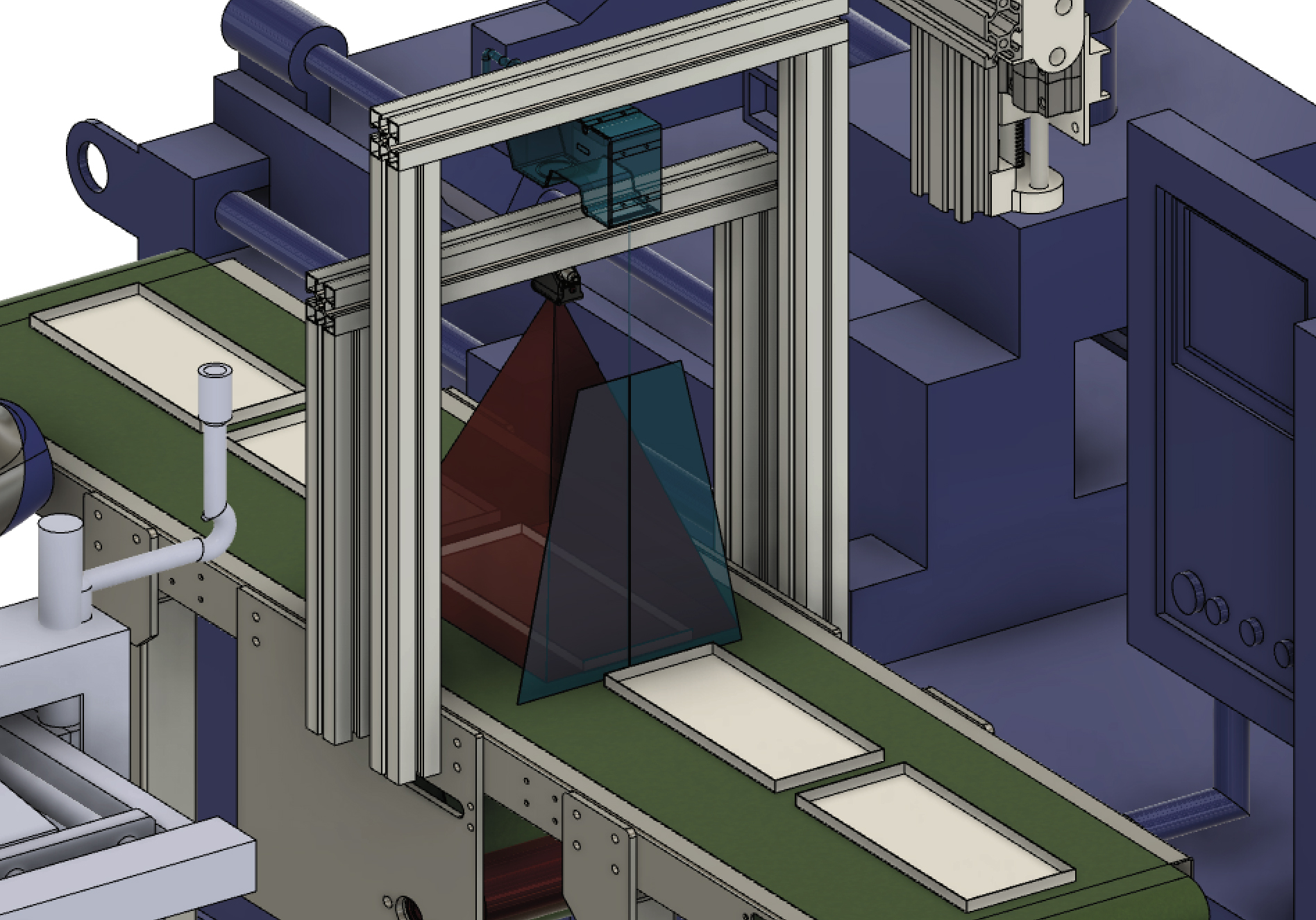

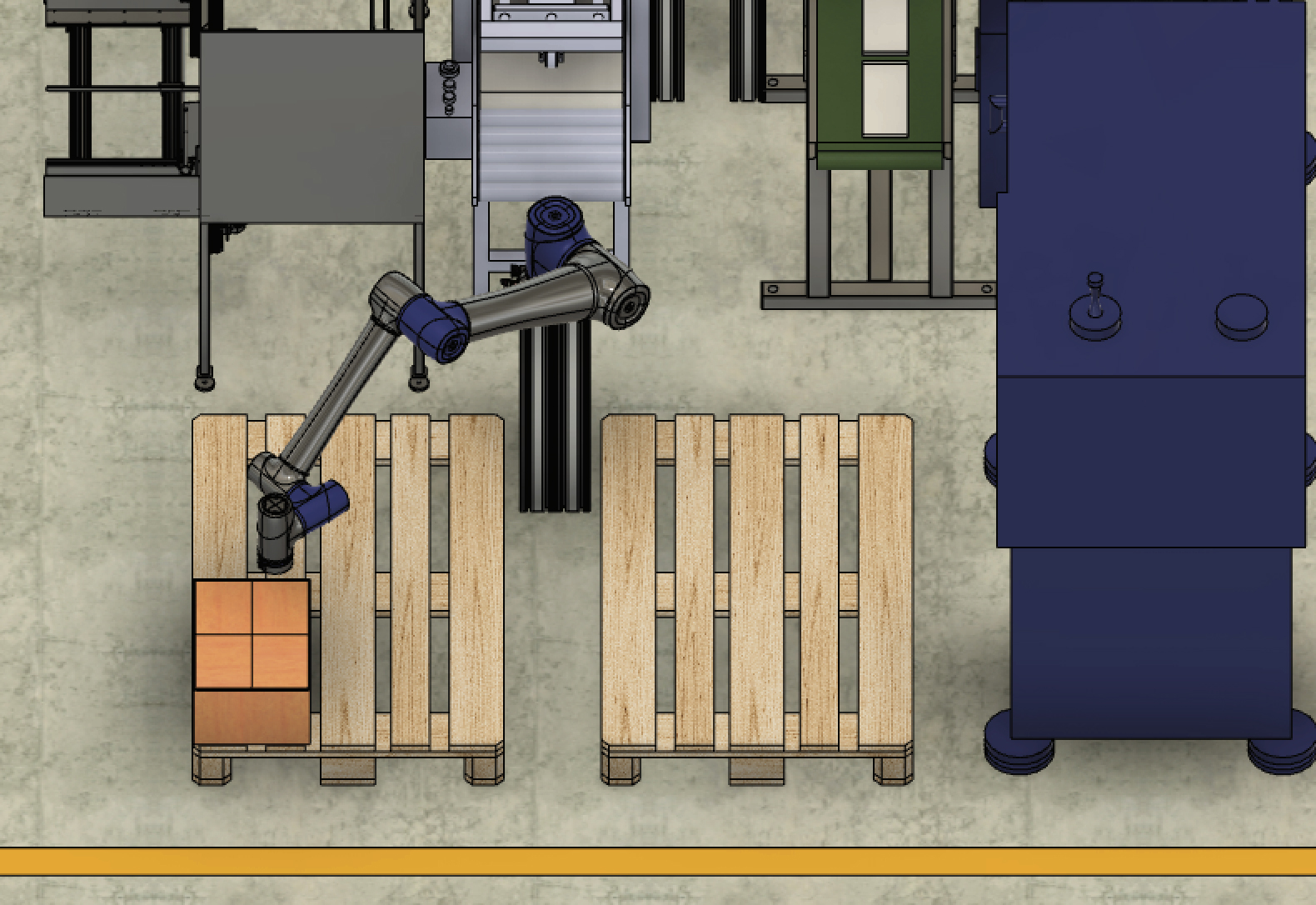

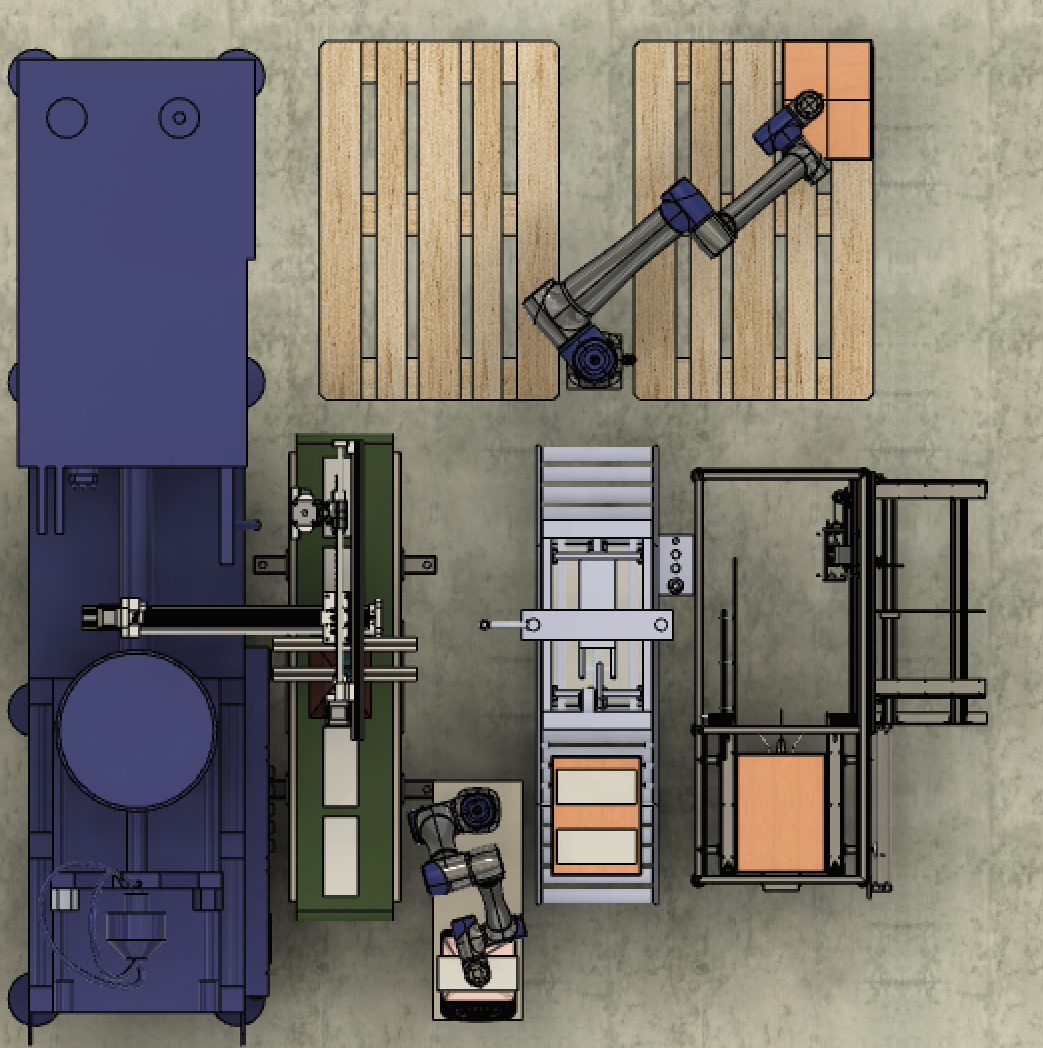

Our cutting-edge Robotic Dimension Control, Packaging, and Palletizing System, exclusively engineered and manufactured by Axl Imperial, combines robotics and machine vision technology. It consists of four stages: Quality Control Station, Weighing and Packaging Station, Carton Formation and Sealing Station, and Palletizing Station, seamlessly integrating the production and packaging process of plastic parts.

Enhanced Quality: The system ensures consistent product quality through precise measurements, inspections, and the elimination of human errors, delivering reliable output.

Increased Efficiency: Automation speeds up the quality control process, enabling faster production throughput, improved overall efficiency, and reduced delays.

Cost Savings: By automating quality control procedures, the solution eliminates manual labor, reduces the risk of costly errors, optimizes resource allocation, improves productivity, and lowers operational costs.

Workforce Empowerment: The system allows the client's workforce to transition to more supervisory roles, focusing on process optimization and continuous improvement, further enhancing operational excellence.